The application of sheet metal processing and printing technology in CNC (Computer Numerical Control) machining has promising prospects, particularly in industries that require precision manufacturing, custom designs, and high efficiency

Customization and Rapid Prototyping

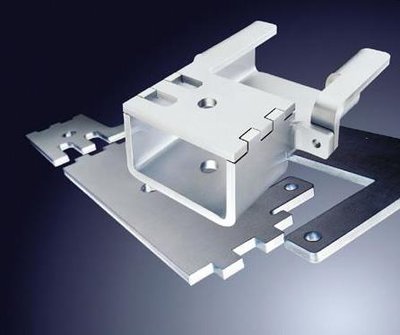

Sheet Metal Processing: CNC machines can be used for precision cutting, bending, and shaping of sheet metal, allowing manufacturers to produce customized parts quickly. This is crucial for industries like aerospace, automotive, and electronics, where custom parts are often required.

Printing Technology: With 3D printing or additive manufacturing, it's possible to produce complex geometries and prototypes that might be too difficult or time-consuming to fabricate with traditional methods. These technologies allow for iterative design and faster production cycles, reducing time-to-market.

Integration with Automation and Smart Manufacturing

Advanced Automation: As part of Industry 4.0, sheet metal processing and printing can be integrated into automated CNC systems. This can streamline production, reduce human error, and increase throughput. Automated systems equipped with CNC machines can perform tasks like cutting, welding, and assembling without constant supervision.

Smart Factory: By connecting CNC machines to IoT networks, manufacturers can monitor real-time data, predict maintenance needs, and optimize operations. This can be extended to sheet metal processing and printing, allowing for smarter production scheduling and resource management.

Material Efficiency and Sustainability

Material Savings: CNC sheet metal processing, combined with printing technology, can improve material utilization by reducing waste. For instance, using 3D printing for certain parts or prototypes eliminates material wastage that often occurs during traditional subtractive manufacturing processes.

Eco-Friendly Manufacturing: With the rise of sustainable practices, combining sheet metal processing with 3D printing enables companies to use recycled or eco-friendly materials more effectively. For example, recycled metal powders in 3D printing can be used in CNC systems, reducing environmental impact

Complex Geometries and Lightweight Structures

Complex Geometries: CNC machines allow for precise cutting of metal sheets into intricate shapes that traditional methods cannot achieve. With the integration of 3D printing, even more complex and lightweight structures can be produced. This is especially beneficial in industries like aerospace and automotive, where lightweight yet strong materials are essential.

Optimization: The combination of sheet metal processing and printing technology allows for design optimization, where complex parts can be fabricated with minimal material usage while maintaining strength and durability

Cost Reduction and Efficiency in Mass Production

Low-Cost Production: The combination of CNC and printing technologies can lead to lower costs for small to medium batch production. CNC machining is precise, and printing technology allows for rapid prototyping and testing, reducing the cost of tooling and molds.

Faster Production: Traditional manufacturing methods often require long lead times for tooling and setup. CNC machines paired with 3D printing technologies can speed up production, especially in industries that require frequent changes or custom designs.

Applications Across Industries

Aerospace: CNC sheet metal processing and 3D printing enable the production of lightweight, high-strength parts with complex geometries for the aerospace industry. Parts like aircraft brackets, housings, and structural components benefit from these technologies.

Automotive: The automotive sector benefits from these technologies in terms of customized parts, prototypes, and tooling, leading to reduced costs and faster development cycles.

Electronics: Precision manufacturing and prototyping of metal parts for electronic devices, especially in consumer electronics and communication equipment, can be enhanced by these technologies.

Medical: Sheet metal processing, combined with additive manufacturing, can create customized implants, surgical tools, and medical devices with complex internal structures.