High-Precision CNC Machining for Complex Molds: The Key to Superior Manufacturing

In today’s fast-paced manufacturing landscape, high-precision CNC machining has become indispensable for producing complex molds with unmatched accuracy and efficiency. As industries demand tighter tolerances and intricate geometries, advanced CNC technology bridges the gap between design complexity and flawless execution.

Applications of CNC Machining in Mold Making

From injection molds for plastic components to die-casting molds for metal parts, high-accuracy mold components are critical for:

Automotive: Engine parts, lighting systems, and interior trim.

Electronics: Micro-components and heat-resistant casings.

Medical: Surgical tools and implantable devices requiring biocompatible materials.

Optimizing Mold Performance with Advanced CNC

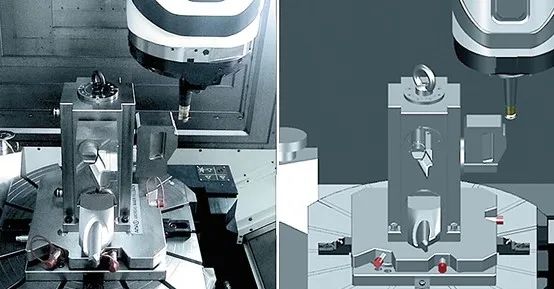

The integration of CAD/CAM software with high-precision CNC machining enables seamless translation of 3D designs into physical molds. Real-time monitoring and adaptive machining further enhance consistency, even for low-volume or custom orders. Key benefits include:

Superior surface finishes for reduced friction and wear.

Repeatability across production runs.

Compatibility with hardened steels, aluminum alloys, and exotic materials.

Choosing the Right CNC Partner

For businesses seeking CNC machining services for complex molds, prioritize providers with expertise in multi-axis CNC machining, material science, and industry-specific certifications (e.g., ISO 9001). Partnering with specialists ensures molds meet performance, durability, and cost-efficiency goals.

Choosing the Right CNC Partner

For businesses seeking CNC machining services for complex molds, prioritize providers with expertise in multi-axis CNC machining, material science, and industry-specific certifications (e.g., ISO 9001). Partnering with specialists ensures molds meet performance, durability, and cost-efficiency goals.

High-precision CNC machining is revolutionizing mold manufacturing, enabling industries to tackle complex designs with confidence. By embracing cutting-edge technology, manufacturers can stay competitive in an era where precision and speed define success.