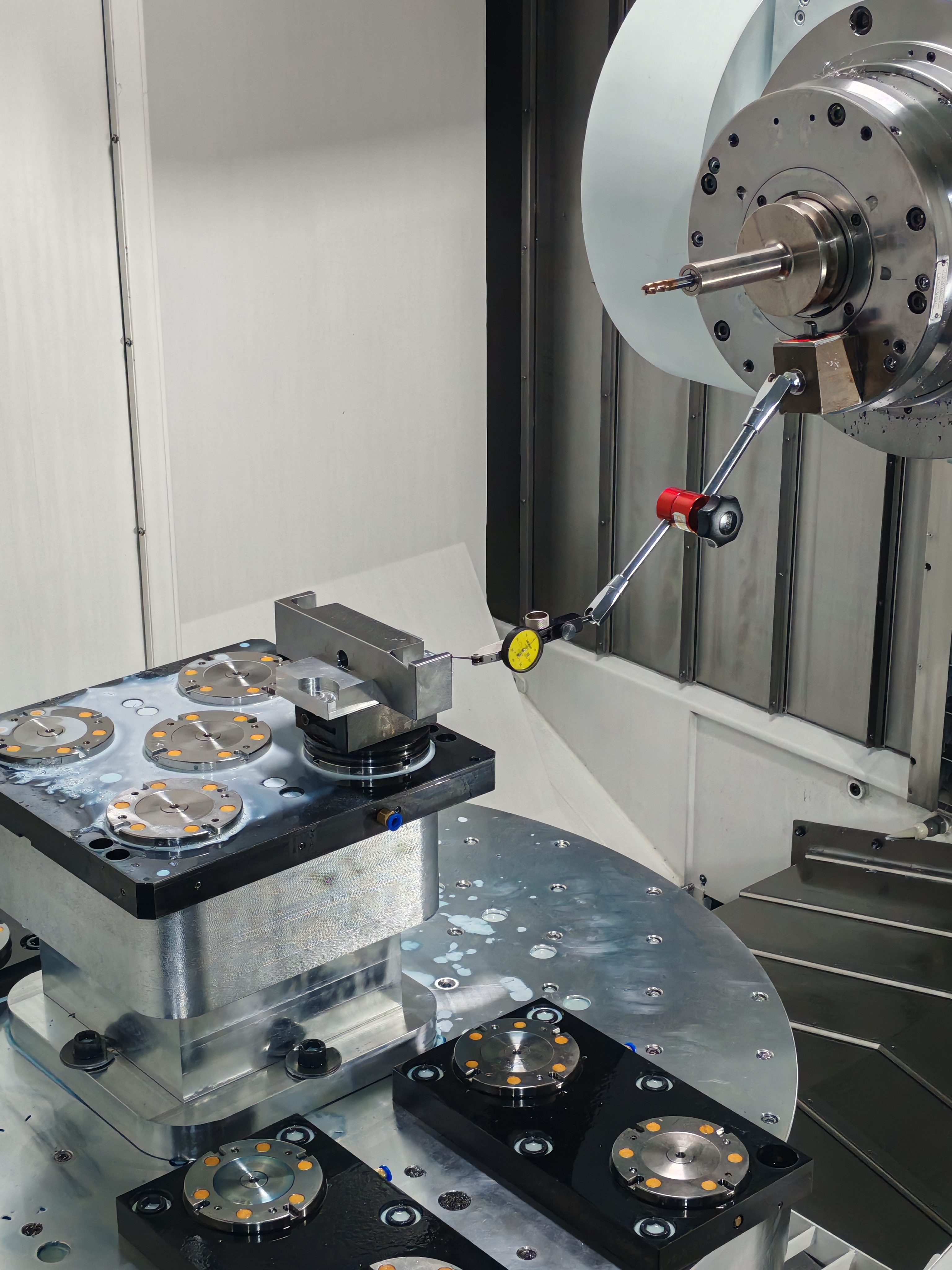

5-Axis CNC Machining

How It Works

Benefits

Applications

1.Widely used in industries such as aerospace, medical, and oil and gas.

2.Ideal for manufacturing components like turbine blades, propellers, and orthopedic implants.

Mechanical structure form

It includes six typical configurations:

1. Double pendulum type (both A and B axes are on the main shaft)

2. Inclined pendulum type (the main shaft is installed at an angle)

3. Double turntable type (A and B axes are on the worktable)

4. One pendulum and one turntable type (combination of pendulum head and turntable)

5. Inclined worktable type

6. Five-axis linkage type

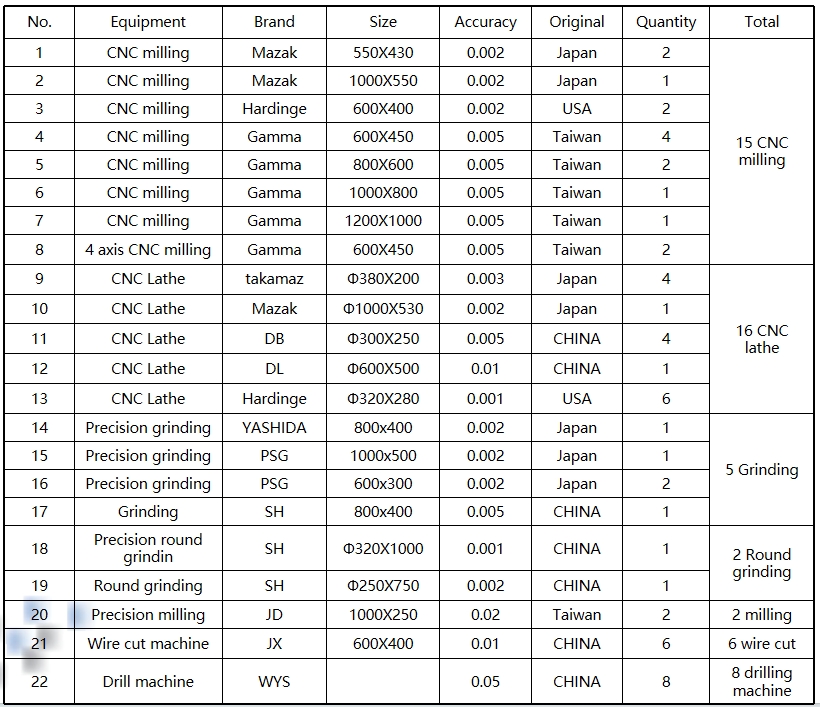

Our other equipment introduction