Injection Molding

Plastic Injection Molding Services for Custom Parts

Our injection molding process handles plastic prototypes and production parts, with a standard lead time of 15 business days.Quick turn injection mold services are available for faster turnaround. We provide expert consultation for smooth transition from design to production. Our manufacturing network in China has a wide range of injection molding machines for producing parts of different sizes

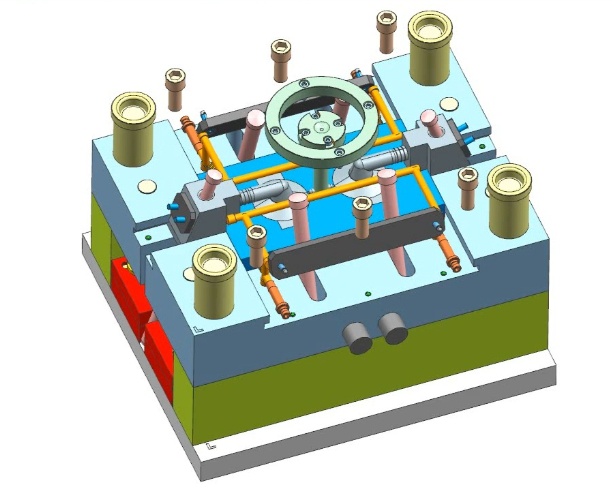

Injection Mold Tooling

Injection molding is a vital process for large-scale manufacturing, encompassing the fabrication and assembly of robust molds made from steel or aluminum to guarantee accurate and consistent part geometries. These molds, crafted from durable materials, are able to withstand the high pressures and temperatures involved in the injection molding process. By utilizing aluminum or steel, injection molding can achieve intricate and detailed part geometries, making it an ideal choice for mass production.

Overmolding

Overmolding enhances product performance and design by integrating multiple materials into a single component, offering features such as ergonomic grips and multi-tone finishes for improved user experience.

Enhances durability and resilience.

Merges diverse materials effortlessly.

Provides a variety of color and texture choices

Insert Molding

The process of mold insert molding involves the integration of metal or other materials into plastic parts during the molding process. This innovative technique offers several benefits, including enhanced strength and reduced assembly time for components with embedded features. By incorporating the metal inserts directly into the plastic part during molding, the need for additional assembly steps is minimized. This not only saves time but also improves the overall durability of the component. Additionally, insert molding helps lower production expenses by streamlining the manufacturing process and eliminating the need for assembly operation

Trusted Experts in Plastic Molding Solutions

Quality control is a top priority for us throughout the injection molding process to ensure the precision and reliability of every plastic component.

We begin by conducting a comprehensive design review to optimize your design for moldability and minimize potential production issues. Our team provides detailed feedback, taking into account the design for manufacturability (DFM) principles.

During production, we implement rigorous in-process quality control measures. Our skilled operators and technicians carefully monitor each step, from inspecting incoming raw materials to conducting final product checks. We utilize advanced inspection tools like CMM, XRF analyzers, and micrometers to ensure precise measurements and consistency.

To guarantee the quality of the final product, we conduct First Article Inspections (FAI), dimensional checks, and functional testing. Each part undergoes a thorough final inspection by expert technicians trained to identify even the smallest discrepancies.

With our ISO 9001:2015 certification and commitment to excellence, we ensure that every part leaving our facility meets the highest standards quality and reliability.

Applications of Injection Molding

Injection molding is a critical process for creating diverse components with precision and efficiency. Key applications by part type include:

Gears: Our process enables the production of high-precision and long-lasting gears, widely used in a variety of mechanical and electronic devices.

Housings: We excel in manufacturing sturdy housings for consumer electronics, automotive components, and industrial machines, providing utmost durability and protection.

Enclosures: With our expertise, we create enclosures specifically designed for electronics, ensuring an exact fit and optimal safeguarding of internal components.

Handles: Our manufacturing capabilities allow for the fabrication of ergonomic and resilient handles for tools, appliances, and other consumer products, offering both comfort and durability.

Caps and Closures: We efficiently manufacture caps and closures for bottles and containers, guaranteeing tight seals and maintaining the integrity of the packaged products.

Connectors: Precision is paramount in electrical and electronic applications, and our process enables us to produce small and intricate connectors to meet the highest standards of accuracy

Injection Molding Solutions

Prototyping Injection Molding

Choose Craft's prototype molding services to rapidly create top-notch prototypes. Our fast turnaround times, versatile material options, and professional Design for Manufacturability (DFM) support enable you to efficiently validate designs and early-stage function testing

Low Volume Injection Molding

Craft offers low-volume production using aluminum tooling, delivering rapid and cost-effective manufacturing solutions for intricate plastic components, ranging from hundreds to thousands of units. Our services are perfect for design validation, inventory management, and providing a flexible supply chain that can adapt to fluctuations in

Mass Production

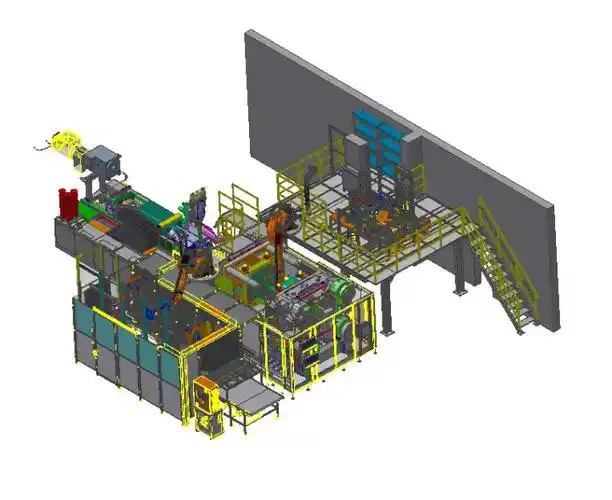

We high-volume injection molding services provide a rapid and cost-effective solution for the mass production of precise and identical parts. Leveraging state-of-the-art equipment and rigorous quality control measures, we guarantee tight tolerances and consistent quality across a wide range of plastic materials tailored to meet your specific requirements.

Why Choose us ?

High Quality Parts:Our production facilities conduct thorough in-process checks and post-production dimensional verifications, ensuring top-tier accuracy and uniformity in custom-molded components, no matter the complexity of the design.

Fast Lead Time:Leveraging accredited local factories and an efficient supply chain network, we drastically reduce the product development timeline, delivering high-quality plastic parts in as little as 2 weeks.

Engineering Support:Connect with our specialists, who bring over a decade of expertise in injection molding, for expert advice on mold design, material selection, and finishing options, guaranteeing a smooth and efficient production process.

Applications of Injection Molding

Insert Molding vs Overmolding

Overmolding molds one part from one material and then molds another material over the first molded part. That’s why it’s sometimes called multi-material molding or, when injection molding is used, two-shot molding.

Insert molding begins when a pre-fabricated, pre-formed, or previously molded part is placed in a mold and then molded over with a different material. Sometimes, the insert is made of metal. However, non-metal inserts can also be used.

With overmolding and insert molding, parts are bonded together seamlessly. Whether it’s to improve comfort, provide sealing, increase safety, or reduce noise and vibration, these two processes are used in a range of applications

FAQ

Q:What are 4 stages of injection molding?

A:Injection molding is a precise process with four key stages for producing high-quality plastic parts:

Clamping: The mold’s two halves are securely clamped together to prevent opening during injection, ensuring the molten plastic stays contained.

Injection: Molten plastic is injected under high pressure into the mold, filling every cavity to form the desired shape.

Cooling: The plastic cools and solidifies within the mold. Controlled cooling ensures the part retains its shape and mechanical properties without defects.

Ejection: Once cooled, the mold opens, and the part is ejected using an automated mechanism, allowing the machine to begin the next cycle.

Q:How much does your injection molding service cost?

A:The pricing for our injection molding services is influenced by several factors, such as the size of the part, mold design complexity, material choice, cavity count, and any additional finishing processes. Since every project is different, we offer customized quotes to give you an accurate cost breakdown based on your specific requirements. Our clear and transparent pricing ensures you know exactly what to expect before moving forward. For an accurate estimate, just submit your project details on our platform, and we’ll evaluate the necessary factors to provide you with a detailed quote

Q:What are the typical tolerances for injection molded parts?

A:In injection molding, achieving accurate tolerances is crucial for ensuring parts fit properly and perform as designed, preventing any potential assembly problems. At Craft, we follow the industry-standard ISO 2768-c for general tolerances, widely accepted for molded components. This standard outlines acceptable tolerance ranges for various features, ensuring consistency and reliability in production. For projects with more demanding tolerance requirements, we are equipped to meet tighter specifications tailored to each client's unique needs. Our flexibility ensures we deliver precisely crafted parts that meet or surpass your expectations.