CNC Machining Service

Why Choose us?

Our team of expert machinists brings unparalleled accuracy to every project, achieving tolerances as tight as 0.01mm. we leverage automated production lines that streamline operations and enhance efficiency. This cutting-edge approach not only accelerates production timelines but also minimizes errors, allowing us to fulfill large orders rapidly and meet your project deadlines with confidence. Experience the future of manufacturing with Carft—where technology meets craftsmanship for exceptional CNC machining solutions.

How CNC Machining Works?

Once the CNC system is activated, the product file is programmed into the software and assigned to the appropriate tools and machinery. These tools and machinery carry out the required cutting tasks. The CNC machining process involves the following stages::

CNC Machining Services for Custom Parts

With state-of-the-art milling and turning equipment, we offer precision machining with tight tolerances of 0.001 inches. Our range of services includes CNC routing, EDM machining, and precision grinding, catering to designers and developers looking for high-quality custom components to bring their innovative ideas to life. Whether your project is simple or intricate, our well-equipped machine shops are prepared to handle it. We assure both exceptional quality and rapid delivery, with simple machined parts shipped within1 day.

Main Processes Of CNC Machining

CNC Milling: Our versatile 3-axis CNC milling machines use rotating tools to precisely remove material from the workpiece. With the option of 4-axis and 5-axis machining, we offer even greater flexibility for high-precision part production.

CNC Turning: Our CNC turning services utilize state-of-the-art technology to swiftly and precisely shape your workpiece. With the use of single-point cutting tools, we remove material from the rotating workpiece, achieving the desired diameter with accuracy. Our CNC lathe machines, equipped with X and Z axes, ensure efficient and high production.

Our Advantages

With our expert team and state-of-the-art equipment, we specialize in precision machining across diverse materials like metal, plastic, and composites. Our comprehensive CNC services cover milling, turning, drilling, grinding, and EDM. From small to large projects, we guarantee top-notch manufacturing quality and adherence to the strict standards

Comprehensive Customization Capabilities

We specialize in providing tailored CNC manufacturing solutions to match your specific needs. Our dedicated team collaborates closely with you from start to finish, guaranteeing on-time and cost-effective delivery. Whether it's rapid prototyping or high-volume production, we've got you covered with our expertise and commitment excellence

MAZAK Five-axis CNC Machine Makes Your Design More Perfect

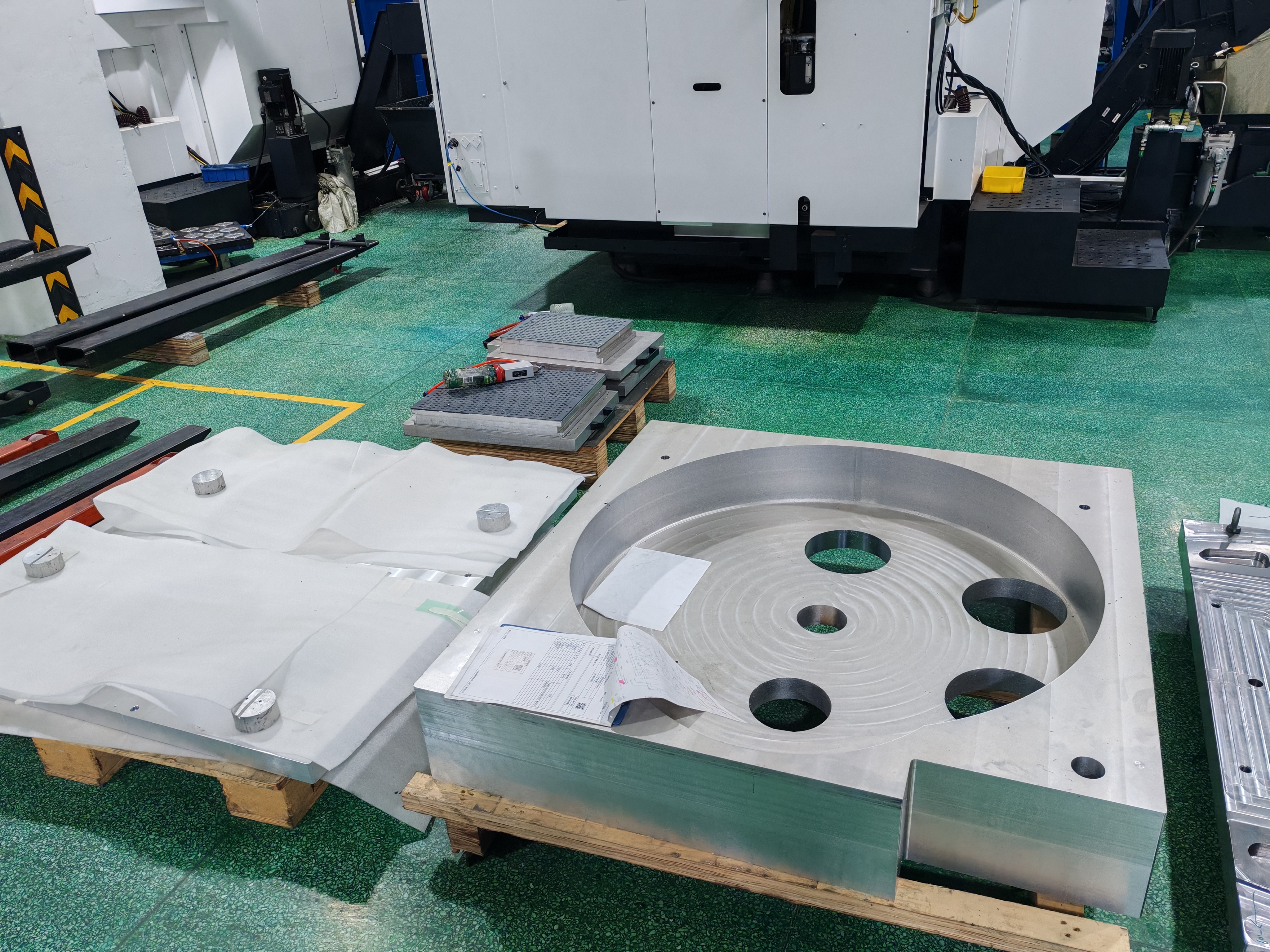

Our Factory

FAQ

Q:What are the applications of CNC machining?

A:Our CNC services offer unmatched versatility and precision for all your custom part production, prototyping, and woodworking needs. With cutting-edge technology and meticulous attention to detail, we deliver consistent quality that meets the highest industry standards. Experience the difference of CNC excellence us.

Q:What is the G and M code in CNC machines?

A:G and M codes drive CNC machines. G-codes control machine movements, like linear and circular interpolation, while M-codes handle machine functions such as powering on/off, spindle control, and coolant. These codes work together to ensure precise and efficient part.

Q:What is machining center and how does it work?

A:A machining center is a versatile CNC machine that combines milling, drilling, and tapping in one setup. It eliminates the need for part transfers between machines, improving efficiency and accuracy. Equipped with a tool turret or magazine, it enables automatic tool changes for swift transitions between operations. Machining centers excel in machining complex parts from various angles, making them essential modern manufacturing.

Q:How long does it take to receive a part once an order is placed?

A:At Craft, the lead time for CNC machined parts varies based on design complexity, material selection, and our production schedule. With our efficient CNC machining process, less complex parts can be delivered in as fast as one day after setup completion. However, for an accurate timeframe specific to your project, we recommend contacting us directly for a detailed quote. We will provide you with a precise lead time based on your unique requirements. Speed and accuracy are our priorities.