Introduction: Special vehicles widely serve various fields of the national economy, such as road transportation, engineering construction, oil fields, mining, electricity, telecommunications, postal services, medical care, sanitation, agriculture, water conservancy, aviation, food, public security, fire protection, justice, and national defense construction. Special vehicles, with their specialized nature, have improved the efficiency of social development, reduced development costs, and promoted social progress. So how are different types of special vehicles manufactured? In what ways can 3D printing change the market for special vehicles?

Manufacturing of Specialty Vehicles

The specialty vehicle market is mostly made up of local manufacturers that specialize in manufacturing police vehicles or specific types of ambulances. More capital-intensive, larger, and more complex vehicles, such as fire trucks, tend to be manufactured by specialists. For example, American companies such as Ferrara or Sutphen are very focused on manufacturing fire trucks in the United States. The Austrian company Rosenbauer produces fire trucks for many international markets. Because this category of vehicles is very different and very different from cars, it is now analyzed separately:

A lot of composite materials are used in this market, especially in Europe.

● People tend to use extruded aluminum profiles, steel plates and aluminum steel plates, and panels and metal sheets can be cut into different shapes by laser cutting or other processes. Bending tools, bending machines and other equipment can also be used for forming manufacturing.

● Welding is mainly done manually, and specialty vehicles use more welding processes than other vehicle categories, especially in the United States.

● Forging, casting processes and some CNC parts are also used in specialty vehicles, but they are rarely used.

● For example, fire trucks have extensive and complex pumping systems and other systems. Some kind of hydraulic components for ladders, lifts or doors are also common. Painting, coating, finishing and some manual craftsmanship are also used.

Market Opportunities

Specialty Vehicles This market seems difficult and there is no room for development. It is generally believed that only large companies will enter such industries because such specialized work will have higher income. It turns out that this market is currently fragmented and consolidation is taking place in the United States. What's more, with the shift to electrification, assembling cars may actually become easier, while this field will continue to be labor-intensive and almost impossible to automate. It is obviously still much easier to develop the automated car market than changing, customizing parts and welding and riveting parts in specialty vehicles.

There has been no increase in investment in this market, and there are almost no breakthrough products or manufacturing innovations. The first electric fire truck in the United States was sold in 2021, and China has more than 420,000 electric buses in operation. There seems to be no real transformative technology that can help the industry, except for very advanced robotic welding capabilities.

3D Printing Opportunities

Many companies have large backlogs and long delivery times. For example, the lead time for ambulances in the US used to be 3 to 6 months, but now it is 12 to 24 months due to increased chassis lead times. Ambulance manufacturers have a shortage of skilled labor, a large backlog of orders, and it takes about 400 hours or more to build an ambulance.

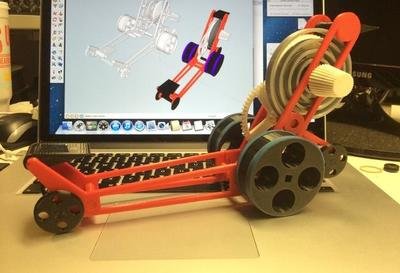

If the industry moves to integrated monocoque cab structures using large-format carbon fiber polymer 3D printing, they will save a lot of time and money. Many places for fasteners, cabinets, and equipment can be integrated into the design. By deploying software such as Twikit or Trinckle, it is easy to show customers many permutations of the design, and then adjust the 3D printed cab design to meet new needs. This will reduce a lot of steel and aluminum, thereby reducing the vehicle's energy and material use, and the material cost will be lower when mass-produced, the weight will be reduced, and there will be much less welding. The fuel efficiency of the vehicle will also be greatly improved. The amount of labor will also be greatly reduced. The lead time for cab components should also be significantly reduced. The overall construction should be much cheaper

In addition, 3D printed shells, tools, and jigs and fixtures will reduce costs. In this custom car, a custom shell made from material extrusion is very cost-effective here. Some low-running molds and casting-like parts can also be made. Molds are made for wheel arches, passenger compartment parts, larger polymer parts and parts in the mechanical area. Custom cable ducts and harness components can also be 3D printed. Overall, a lot of manufacturing aids and intermediate components for 3D printing can really come into play

Composite 3D printing can also handle a lot of large parts. 3D printed molds for silicone, PU and other soft components can come into play in the interior. Reaction injection molding combined with 3D printing can also make many interior components. Lost wax casting and SLA or DLP can also be used to make small metal parts. ExOne sand casting for molds can also really help to make low-volume run metal parts at a relatively cheap price. Binder jetting can be used for some cheap parts, and desktop FDM printers can also be used to make short-run parts. FDM and polymer powder bed fusion are also very suitable for making final parts.