February 2025 – As industries continue to evolve, the demand for precision and efficiency in manufacturing processes has led to an increased reliance on CNC (Computer Numerical Control) machining. This technology, which involves the use of computers to control machine tools such as mills, lathes, and routers, is transforming the manufacturing landscape, providing businesses with enhanced productivity, greater accuracy, and cost-effective solutions.

Precision and Versatility Drive Industry Growth

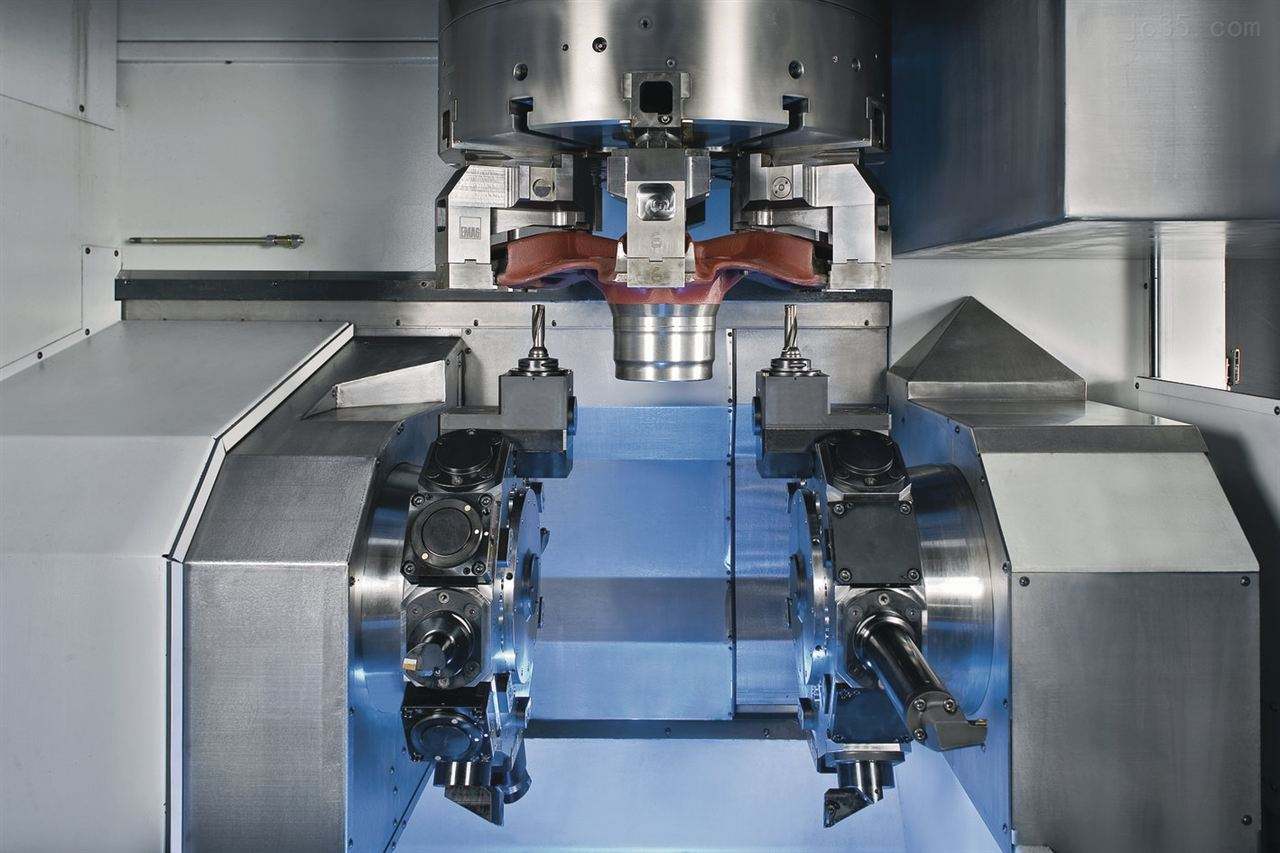

One of the primary drivers behind the expansion of the CNC machining industry is its unmatched precision. With tolerances often as tight as 0.01mm, CNC machines can produce highly intricate and complex parts that are crucial for sectors such as aerospace, automotive, medical, and electronics. As the need for intricate, high-quality components increases, so does the demand for CNC machining, which can handle a variety of materials ranging from metals like aluminum and titanium to plastics and composites.

The versatility of CNC machines also contributes to their growing popularity. These machines can produce a broad range of products, from small-scale custom parts to large quantities of mass-produced components. As industries strive to innovate and develop cutting-edge technologies, CNC machining provides the flexibility necessary to meet these diverse demands, making it indispensable in modern manufacturing.

Innovation and Advancements in CNC Technology

The CNC machining industry is not standing still. Recent advancements have further propelled its capabilities. The introduction of multi-axis machines, for example, has allowed manufacturers to create even more complex geometries in a single setup, reducing production time and costs. Additionally, the integration of artificial intelligence (AI) and machine learning into CNC systems is paving the way for smarter, self-optimizing machines that can detect issues and make adjustments in real-time.

3D printing, another emerging technology, is also making its mark within the CNC sector. Many CNC machining shops are adopting hybrid systems that combine traditional CNC operations with additive manufacturing techniques, offering more advanced solutions for prototyping and part production.

Impact on Global Supply Chains

CNC machining has become a cornerstone of global supply chains, as it enables high-speed, high-precision manufacturing in a wide range of industries. The ability to produce quality parts quickly and with minimal human intervention has made it an attractive option for companies looking to streamline production and reduce lead times. In addition, with the ability to replicate designs exactly, CNC machining ensures consistency, which is crucial for industries where precision is paramount.

As the global demand for fast, high-quality manufacturing continues to rise, CNC machining is expected to remain a key enabler of innovation and efficiency in the production of everything from consumer electronics to medical devices.

The Future Outlook for CNC Machining

The future of CNC machining looks incredibly promising. With continued advancements in technology, such as automation, artificial intelligence, and enhanced materials, the industry is poised to grow even further. Furthermore, as more companies embrace sustainability, the focus on energy-efficient CNC machines and eco-friendly manufacturing practices is expected to increase, making CNC machining even more attractive for industries aiming to meet sustainability goals.

In conclusion, CNC machining is not only revolutionizing the way products are made, but it is also shaping the future of manufacturing in a world that demands ever-greater precision, efficiency, and innovation. As industries across the globe continue to evolve, CNC machining will undoubtedly remain at the forefront of these advancements.