In today's fast-paced manufacturing industry, innovation and efficiency are crucial for businesses to stay competitive. Among the technologies that have revolutionized the manufacturing landscape, Computer Numerical Control (CNC) machining stands out as a game-changer. In this industry news article, we will explore how CNC machining is transforming manufacturing processes and unlocking new possibilities for businesses

The Rise of CNC Machining

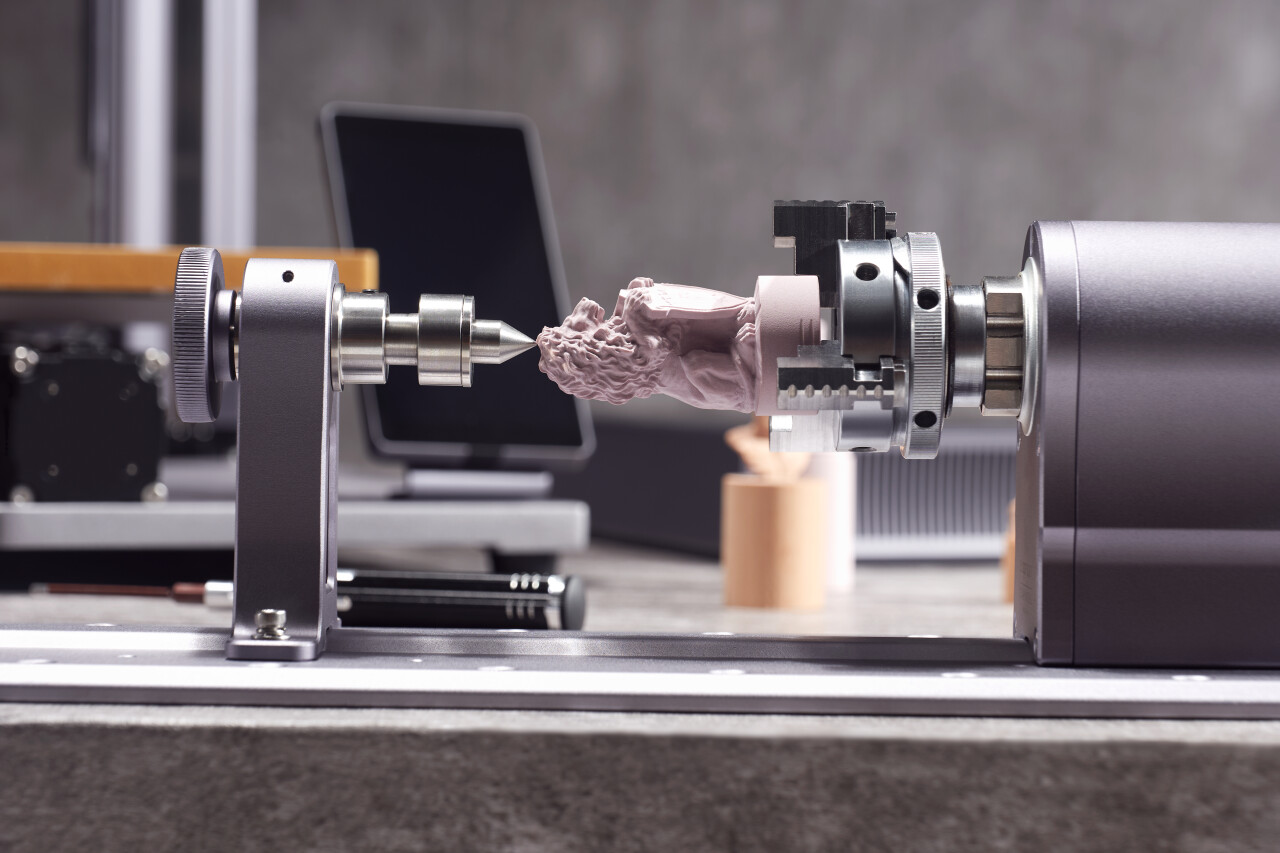

Over the years, CNC machining has gained immense popularity due to its precision, speed, and versatility. Unlike traditional manufacturing methods, which heavily rely on manual labor, CNC machining employs computer-controlled machines to perform various tasks with exceptional accuracy. From cutting and shaping to.

Enhanced Precision and Consistency

CNC machining offers unparalleled precision and consistency, making it ideal for creating complex components with tight tolerances. The computer-controlled nature of CNC machines ensures that each part produced is an accurate replica of the original design. This level of precision eliminates the inconsistencies and errors that can occur with manual machining methods, leading to higher-quality end products.

Streamlined Production Processes

CNC machining has significantly streamlined production processes, reducing overall lead times and increasing productivity. Once the design is programmed into the CNC machine, it can effortlessly reproduce the same part repeatedly, even at high volumes. This automation reduces the dependency on manual labor, minimizes human error, and enhances overall production efficiency.

Drilling and Milling, CNC machines bring unprecedented efficiency and consistency to the production line.

Material Flexibility and Innovation

Another advantage of CNC machining is its ability to work with a wide range of materials, including metals, plastics, composites, and even ceramics. This material flexibility allows manufacturers to explore innovative design possibilities and push the boundaries of what can be created. From intricate aerospace components to custom medical implants, CNC machining enables the production of highly complex and tailored parts

Cost-Effective Manufacturing

Despite its cutting-edge technology, CNC machining offers cost-effective manufacturing solutions to businesses. The initial investment in CNC machines may seem high, but the long-term benefits outweigh the upfront costs. With reduced labor requirements, minimal material wastage, and improved efficiency, CNC machining helps businesses optimize their production processes and achieve significant cost savings in the long run.

Advancements in CNC Technology

The CNC machining industry continues to evolve rapidly, thanks to advancements in technology. Today, we see the integration of artificial intelligence (AI) and machine learning algorithms into CNC machines, further improving their capabilities. These intelligent systems enable real-time monitoring, predictive maintenance, and adaptive machining, ensuring optimal performance and uptime.

CNC machining has emerged as a game-changer in the manufacturing industry, empowering businesses to produce high-quality, intricate parts with remarkable efficiency. Its precision, consistency, material flexibility, and cost-effectiveness make it a go-to technology for manufacturers across various sectors. As CNC technology continues to evolve, we can expect further advancements that will redefine manufacturing processes and drive innovation to new heights. In an industry that demands constant progress, CNC machining remains at the forefront, reshaping the way products are made and setting new standards for excellence in manufacturing

.