Injection Molding Industry: Unveiling the Future Trends

In the dynamic landscape of manufacturing, the injection molding industry is on the cusp of significant transformation, driven by technological advancements, market demands, and global trends. As we look ahead, several key developments are set to reshape this crucial sector.

Market Expansion on the Horizon

The global injection molding market is on a growth trajectory. Estimated at USD 285.5 billion in 2023, it is projected to expand at a Compound Annual Growth Rate (CAGR) of 4.9% from 2024 to 2030. This growth is fuelled by the increasing demand for injection - molded components, especially in the automotive industry. For example, in the US, the burgeoning electric vehicle (EV) market is driving the need for lightweight plastic exterior components. Hyundai Motor Group's new EV factory in Georgia, set to open in 2025 with an annual capacity of 300,000 vehicles, is a testament to this trend. The federal government's support through tax rebates and subsidies further boosts the demand for EVs, thereby increasing the need for injection - molded parts in both traditional and electric vehicles.

Technological Innovations Propelling Change

AI - Driven Smart Manufacturing: The integration of artificial intelligence (AI) and the Internet of Things (IoT) is revolutionizing injection molding. AI - powered systems can monitor and adjust critical parameters like temperature, pressure, and cycle times in real - time, optimizing the production process. Predictive maintenance, another AI - enabled feature, tracks equipment wear and tear, predicting potential failures and preventing costly downtime.

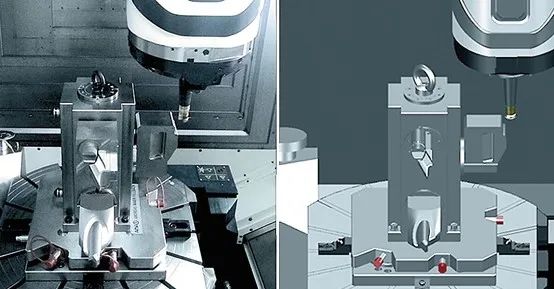

Advanced Molding Processes: Composite injection molding techniques are making strides. The hot - press injection one - piece molding technology, which combines fiber - reinforced composites with injection molding, shortens production cycles and enhances product strength and stiffness. In the consumer electronics sector, the In - Mold Electronics (IME) technology is being widely adopted, embedding electronic components directly during the injection process, reducing subsequent processing steps and improving overall product performance.

Sustainable Practices Taking Center Stage

Green Materials: With the growing global focus on environmental protection, the use of eco - friendly materials is on the rise. Biodegradable plastics and materials derived from renewable resources are being increasingly used in injection molding. These materials not only reduce environmental impact but also meet the growing consumer demand for green products.Energy - Efficient Operations: All - electric injection molding machines are replacing traditional hydraulic equipment. These electric machines are more energy - efficient, reduce reliance on fossil fuels, eliminate the use of hydraulic oil and its associated environmental risks, and significantly lower carbon footprints.

Meeting Challenges on the Path to Progress

Despite the promising outlook, the injection molding industry faces challenges. The high cost of eco - friendly materials may hinder their widespread adoption. Moreover, the implementation of new technologies requires substantial investment in equipment upgrades and staff training. However, these challenges also present opportunities for innovation and growth, as companies strive to find cost - effective solutions and improve their competitiveness.

In conclusion, the injection molding industry is on the verge of a new era, characterized by technological innovation, sustainable development, and market expansion. Companies that embrace these trends and adapt to the changing landscape will be well - positioned to thrive in the future.