When discussing the characteristics of five-axis machines, it is necessary to compare them with traditional three-axis equipment. Three-axis machining equipment is quite common in production, including stand-type, bench-type, and gantry-type among others. Common processing methods include end-cutting with a vertical milling cutter, side-edge cutting, and conformal machining with ball-end mills, etc. However, regardless of the form or method, they all share a common feature: the tool axis direction remains unchanged throughout the machining process. The machine can only achieve the movement of the tool in the three-dimensional Cartesian coordinate system through interpolation of the X, Y, and Z linear axes.

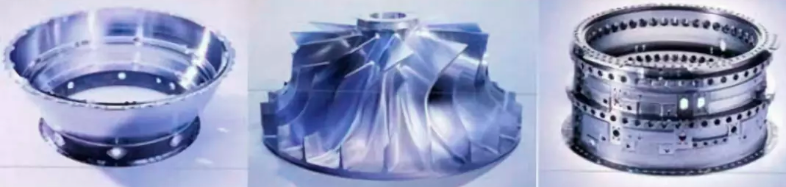

Therefore, when dealing with the following products, the drawbacks of low efficiency, poor surface quality, and even inability to process with three-axis CNC equipment become apparent.

1.Compared with three-axis CNC machining equipment, five-axis CNC machines have the following advantages:

Maintain the optimal cutting condition of the tool and improve the cutting conditions.

Maintain the optimal cutting condition of the tool and improve the cutting conditions.

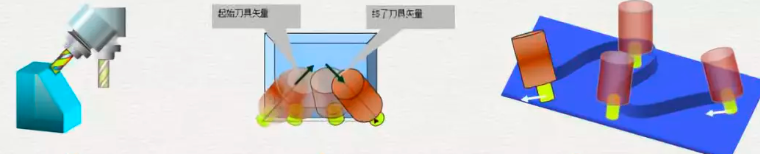

As shown in the figure, in the left image, with the three-axis cutting method, when the cutting tool moves towards the top or the edge of the workpiece, the cutting condition gradually deteriorates. To maintain the optimal cutting condition here, it is necessary to rotate the worktable. If we want to complete the processing of an irregular plane completely, we must rotate the worktable in different directions multiple times. As can be seen, the five-axis machine tool can also avoid the situation where the center point of the ball-end milling cutter has a zero linear speed, achieving better surface quality.

2.Effectively avoiding tool interference

As shown in the figure, for parts such as impellers, blades, and integral disk used in the aerospace field, three-axis equipment cannot meet the process requirements due to interference. However, the five-axis machine tool can. At the same time, the five-axis machine tool can use shorter tools for processing, improving the system rigidity, reducing the number of tools, and avoiding the generation of dedicated tools. For our business owners, it means that in terms of tool costs, the five-axis machine tool will save you money!

3.Reduce the number of clamping times and complete five-sided processing in one setup

As can be seen from the figure, the five-axis machining center can also reduce the reference conversion and improve the processing accuracy. In actual processing, only one setup is required, and the processing accuracy is easier to be guaranteed. At the same time, due to the shortening of the process chain and the reduction of the number of equipment, the number of tooling fixtures, the floor area of the workshop, and the equipment maintenance costs also decrease. This means that you can complete more efficient and higher-quality processing with fewer fixtures, less workshop area, and lower maintenance costs!

4.Improve processing quality and efficiency

As shown in the figure, the five-axis machine tool can adopt side-edge cutting of the tool, resulting in higher processing efficiency.

5. Shorten the production process chain and simplify production management

The complete processing of a five-axis CNC machine tool significantly shortens the production process chain and simplifies production management and planning scheduling. The more complex the workpiece is, the more obvious its advantages over the traditional process-dispersed production method become.

6. Shorten the development cycle of new products

For enterprises in fields such as aerospace and automobiles, some new product parts and forming molds have very complex shapes and high precision requirements. Therefore, a five-axis CNC machining center with high flexibility, high precision, high integration and complete processing capabilities can effectively solve the problems of precision and cycle in the processing of complex parts during the new product development process, significantly shortening the development cycle and improving the success rate of new products.