3D printing, also known as additive manufacturing, is a process used to create three-dimensional objects from a digital file. Unlike traditional manufacturing methods that subtract material from a larger block (like machining), 3D printing adds material layer by layer to build the object. It’s particularly useful for creating complex shapes that would be difficult or impossible to achieve with other methods.

Creating a Digital Model:

The process begins by creating a 3D model of the object to be printed. This model is usually designed using CAD (Computer-Aided Design) software or 3D scanning.

Once the design is complete, it is saved in a format that the 3D printer can understand, such as STL or OBJ.

Slicing the Model:

The 3D model is then "sliced" into thin horizontal layers. This slicing process breaks down the 3D design into 2D cross-sections.

The slicing software generates a set of instructions (often called G-code) that tells the 3D printer how to move, where to deposit material, and how thick each layer should be.

Printing the Object:

The 3D printer reads the G-code and begins the printing process, starting at the bottom of the object and building it layer by layer.

Materials are deposited through a nozzle, typically using one of several different methods, depending on the type of 3D printer being used.

Layer by Layer Construction:

As each layer is printed, it fuses with the layer below it. The material can either be a plastic filament, resin, metal powder, or other substances, depending on the type of 3D printing technology.The printer continues adding layers until the entire object is complete.

Post-Processing:

After printing, some objects may require additional work, such as support removal, sanding, painting, or curing (in the case of resin-based prints).Some 3D printed objects need to be hardened or strengthened depending on the material used (for example, UV light curing for resin prints).

Materials Used in 3D Printing

3D printing can work with a variety of materials, including:

Plastics (PLA, ABS, PETG, Nylon)

Resins (used in SLA/DLP printers)

Metals (stainless steel, titanium, aluminum)

Ceramics (used for artistic or functional objects)

Composites (materials with additives like carbon fiber or glass fibers for increased strength)

Advantages of 3D Printing

Customization: It allows for highly customized and complex designs.

Rapid Prototyping: You can quickly create prototypes and make adjustments to designs.

Material Efficiency: 3D printing typically generates less waste compared to traditional methods (since it adds material rather than subtracting it).

Reduced Lead Time: It reduces the time from design to production, which is especially useful in industries like aerospace, medical, and automotive.

Applications of 3D Printing

Prototyping: Designers use it to quickly test ideas and refine concepts.

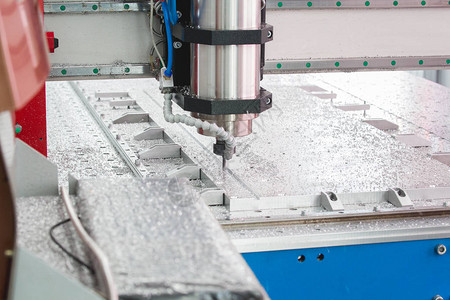

Manufacturing: 3D printing can be used for small to medium-sized production runs, especially for complex or custom parts.

Medical: Creating customized implants, prosthetics, or anatomical models for surgery.

Architecture: Building models and even printing parts of buildings or homes.

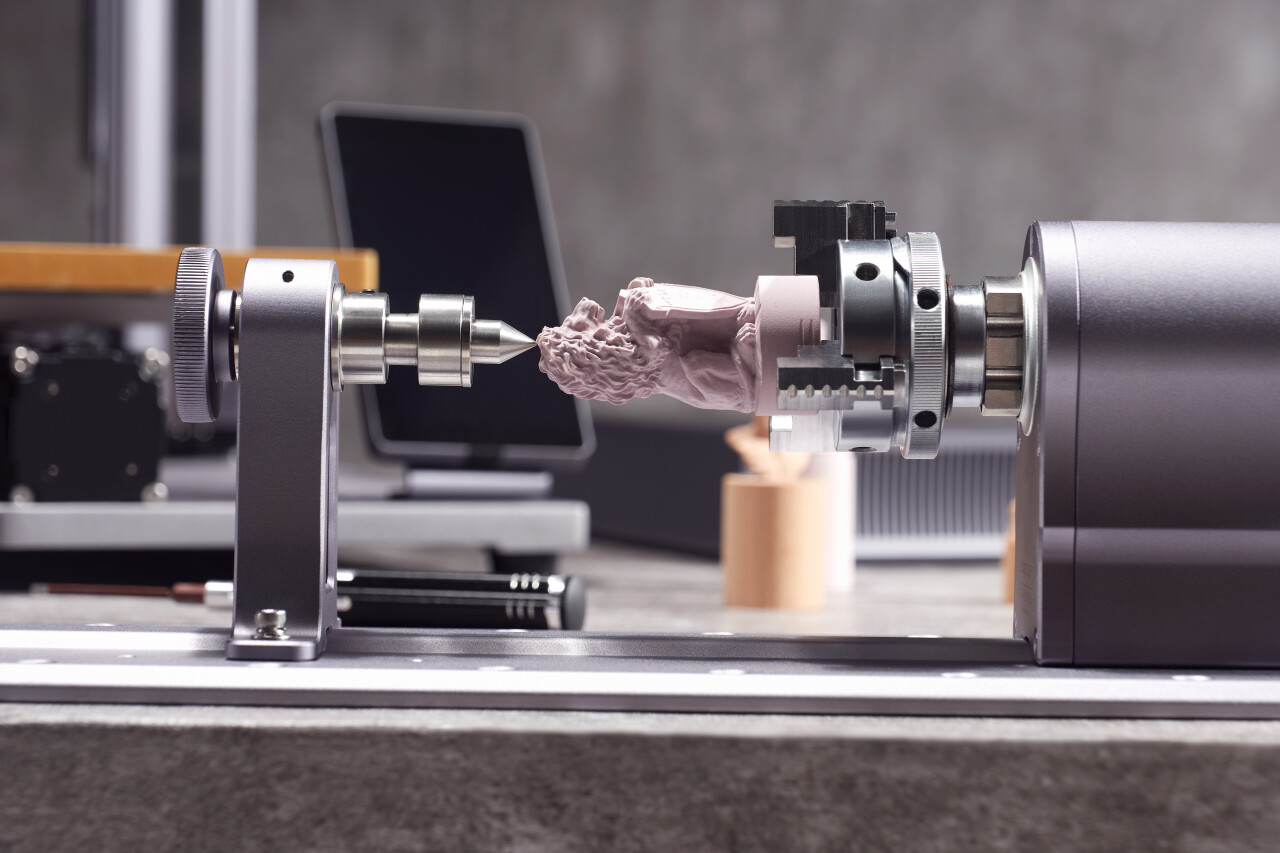

Art & Jewelry: Artists and designers use 3D printing to create detailed sculptures and intricate jewelry designs.

Aerospace & Automotive: Printing lightweight parts and components for advanced machinery or vehicles.

There are several different 3D printing methods, each using a different process for material deposition:

Fused Deposition Modeling (FDM):

Stereolithography (SLA):

Selective Laser Sintering (SLS):

Digital Light Processing (DLP):

Multi Jet Fusion (MJF):