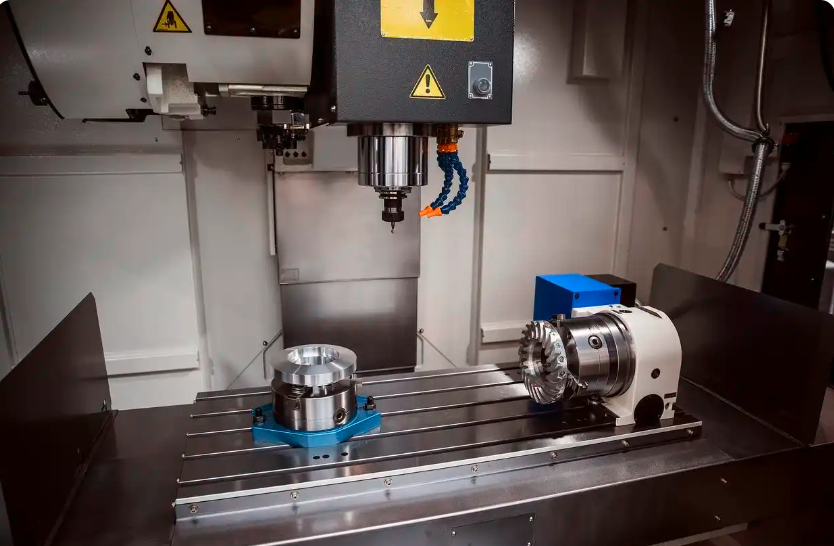

Three-axis machining center: Vertical and Horizontal

The main technical features of a three-axis machining center lie in its three linear motion axes: X, Y, and Z.

This type of machining center usually comes in two types: vertical and horizontal.

The spindle of a vertical machining center is perpendicular to the worktable, making it suitable for processing small and lightweight parts; while the spindle of a horizontal machining center is parallel to the worktable, which is suitable for processing large and heavy parts.

The functions of a three-axis machining center mainly include milling, drilling, boring, etc., and it is suitable for processing various complex shapes.

Four-axis machining center: Adding a rotating axis to enhance processing accuracy and efficiency

The four-axis machining center adds an additional rotating axis on the basis of the three-axis, usually the A-axis or the B-axis.

The A-axis rotates around the X-axis, and the B-axis rotates around the Y-axis. The rotating axis of the four-axis machining center can increase the processing angle of the workpiece, improving the processing accuracy and efficiency.

Its functions mainly include complex surface processing, drilling, milling, etc., and is widely used in the manufacturing industries such as aviation and automobiles.

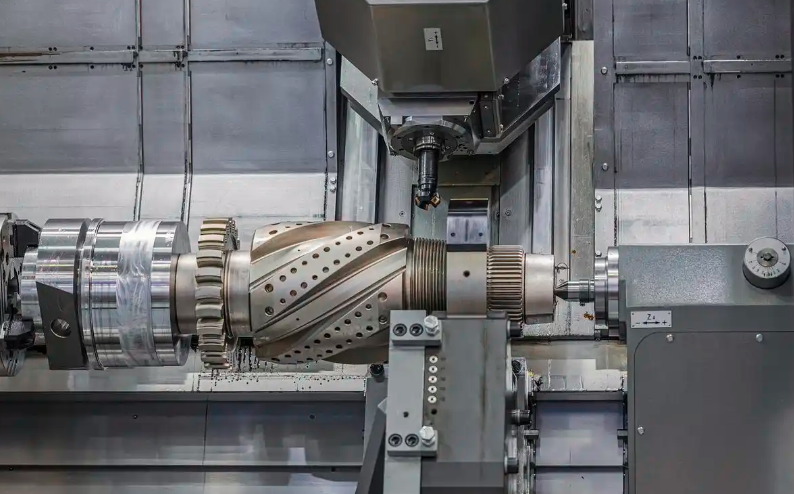

Five-axis machining center: Achieving processing of spatial curves and surfaces

The five-axis machining center adds an additional tilt axis on top of the four-axis system, usually the C-axis or the inclined A-axis.

This tilt axis enables the tool to maintain the optimal cutting angle during the machining process, thereby achieving high-precision processing of spatial curves and

surfaces:

The functions of the five-axis machining center are more powerful, capable of completing various difficult and complex processing tasks, such as the machining of complex curved surface parts like impellers and blades. Conclusion

Three-axis, four-axis and five-axis machining centers each have their own technical features and functional advantages, and can meet the processing requirements of different manufacturing industries.